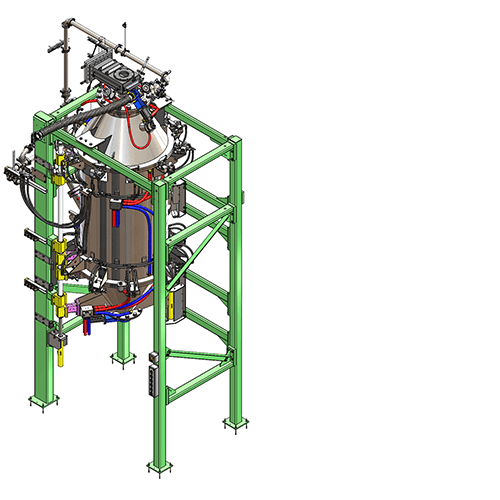

At Re:Build DAPR, we specialize in the design, development, and integration of custom reactors for complex industrial and research applications. From chemical processing to advanced materials synthesis and clean energy production, our reactor systems are engineered for performance, scalability, and safety. Whether you are developing a novel reaction pathway or scaling a proven process, we build reactors that deliver results and withstand the realities of deployment.

Reactors are the heart of many transformative technologies. But off-the-shelf designs rarely meet the requirements of first-of-kind processes or harsh conditions. We work from first principles to deliver systems that perform in the lab, in the field, and at scale.

We design around your specific reaction pathway, throughput needs, and materials, whether batch, continuous, or hybrid.

We prioritize thermal management, safety, and system responsiveness to ensure consistent results and reliable operation.

From early feasibility through pilot plants and commercial deployment, our designs are ready to grow with your vision.

We engineer reactors from the ground up, designed to meet your exact technical, environmental, and process goals.

Process, mechanical, materials, automation, and thermal experts collaborate from day one.

We’ve built reactors for high-temp, high-pressure, corrosive, and cryogenic conditions.

We support every step, from concept and design to build, test, and install, all under one roof.

Every reactor is engineered not just to function, but to scale.

Fill out the form below and someone from the Re:Build DAPR team will be in touch with you shortly.