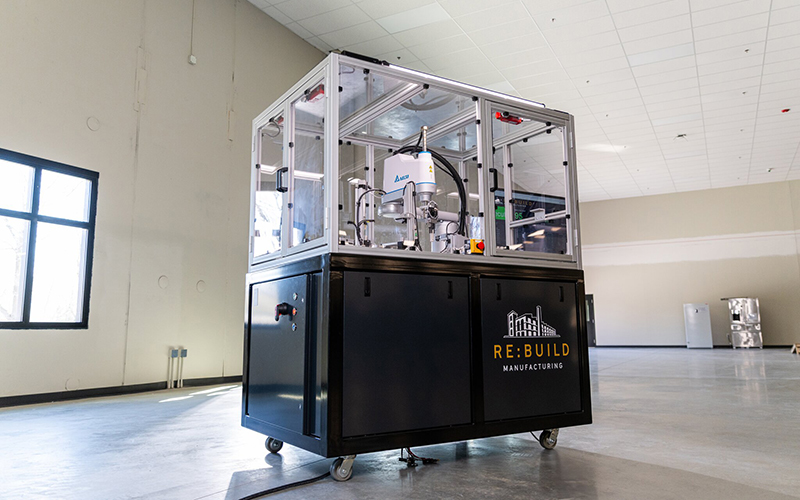

At Re:Build DAPR, we don’t just design equipment, we build and deliver fully integrated, production-ready systems. Our turnkey development approach unifies design, engineering, controls, and assembly under one roof, accelerating time-to-value and eliminating the friction of handoffs and misalignment.

We partner with you from concept to commissioning to deliver systems that are fully functional, thoroughly tested, and built to scale. Every project is supported by a dedicated project manager who oversees the entire lifecycle, ensuring seamless communication, efficient execution, and alignment from start to finish. Our process emphasizes collaboration, integration, and speed to deployment.

We manage the full lifecycle, from napkin sketch through design, build, testing, and on-site commissioning. This means you do not have to juggle multiple vendors or stages.

Our mechanical, controls, and system engineers work side by side to build unified systems that operate seamlessly.

We turn plans into operational systems that are complete, tested, and ready to run on day one.

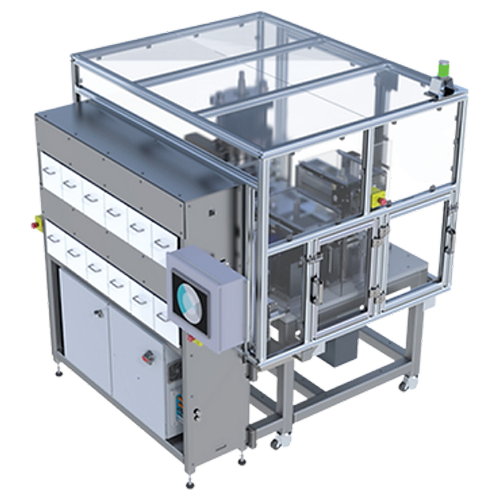

We build systems that do more than function, they drive operational efficiency, reduce downtime, and scale intelligently with your business. Our turnkey solutions include:

Complete mechanical, electrical, and control systems tailored to your process requirements.

Vendor sourcing and build oversight, with fabrication managed in-house or through qualified partners.

Hands-on integration and validation, including dry-runs and factory acceptance testing (FAT).

On-site setup, site acceptance testing (SAT), process tuning, operator training, and support to ensure a smooth startup.

We own every step of the process, from napkin sketch to operational system.

Our systems are never siloed. We ensure they plug into your existing infrastructure, upstream and downstream, with minimal disruption.

Whether you need a standalone system, a modular platform, or an integrated production line, we tailor our development scope to your exact needs.

We don’t just build machines, we engineer solutions that integrate seamlessly into your broader operational system. Our approach is always grounded in your specific application and performance goals.

Technical and operational risks are identified early in the process to minimize surprises later. By proactively surfacing potential challenges, we help ensure smoother development, faster deployment, and long-term reliability.

Our work goes beyond concepts. We deliver fully functioning systems that solve real manufacturing problems on time, on budget, and aligned with your needs. Every project is supported by a dedicated project manager who keeps things on track from kickoff to commissioning.

Fill out the form below and someone from the Re:Build DAPR team will be in touch with you shortly.