Equipment Development & Integration

At Re:Build DAPR, we specialize in developing and integrating industrial equipment that bridges the gap between technology development and scalable manufacturing. Our team works with clients to accelerate the commercialization process, ensuring that novel technologies are not just functional in a lab setting, but fully manufacturable and ready for deployment.

We help companies bridge the gap between research and full-scale production, ensuring that advanced engineering concepts become manufacturable, high-performance systems. Whether supporting startups or established industrial leaders, Re:Build DAPR provides the expertise needed to accelerate commercialization and de-risk product development.

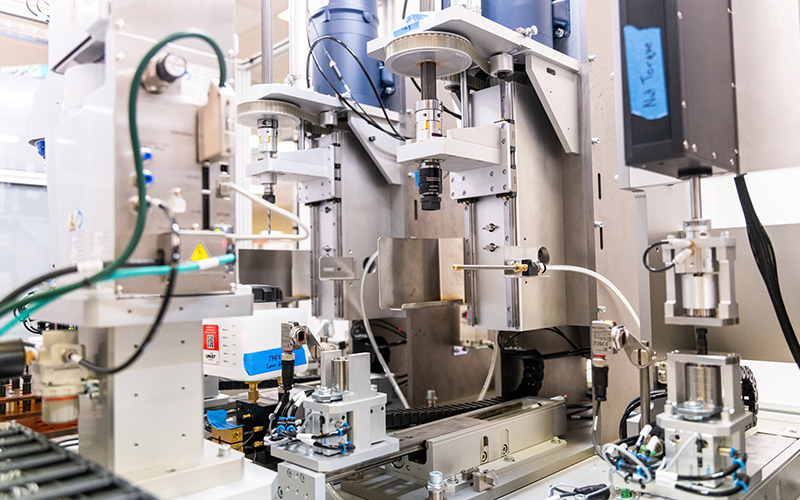

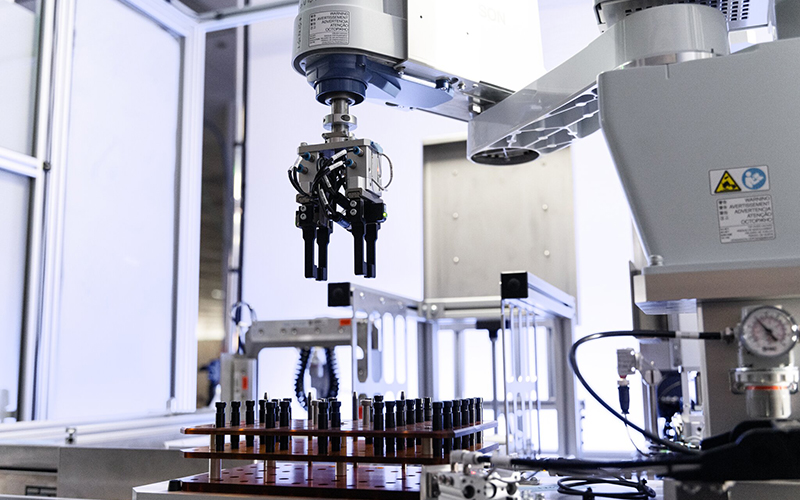

Re:Build DAPR automates processes that have never been automated before, designing both the equipment and the manufacturing process. We transform manual lab and production tasks into scalable, automated workflows.

Our expertise lies in solving non-standard automation challenges, whether it’s reclaiming materials, refining delicate assembly techniques, or handling unique components.

Re:Build DAPR optimizes entire systems, not just individual components, ensuring seamless integration from design to fabrication and commissioning. We enhance efficiency and synergy across industrial operations by delivering fully operational, end-to-end solutions.

We engineer advanced control systems that ensure precision, efficiency, and safety in industrial operations. Our expertise spans PLCs, industrial automation, and sensor integration, enabling seamless data acquisition and optimized performance.

Our focus is on intelligent control solutions that enhance operational reliability and process automation across complex systems.

Engineering Analysis

Re:Build DAPR’s engineering analysis services provide clients with critical, data-driven insights that optimize designs, reduce risks, and improve overall project success. By applying first principles of engineering, we ensure that every decision is grounded in rigorous analysis, leading to robust and manufacturable solutions.

We leverage state-of-the-art simulation and modeling tools to predict system performance and validate design integrity. Whether evaluating the feasibility of new product concepts or assessing the scalability of a manufacturing process, Re:Build DAPR delivers actionable insights that help clients move forward with confidence.

Re:Build DAPR evaluates new product concepts for both technical and economic viability, ensuring that clients receive clear, data-driven insights to guide development. Our feasibility assessments help identify the best strategies for scalable commercialization.

Re:Build DAPR performs comprehensive engineering calculations to validate design integrity and optimize performance. Our finite element analysis (FEA) simulations model mechanical and structural behaviors, ensuring that products meet the highest standards of reliability and efficiency.

We collaborate closely with clients from project conception to identify and mitigate technical, operational, and supply chain risks. By addressing uncertainties early, we help ensure a smooth path to commercialization.

Specialized Applications

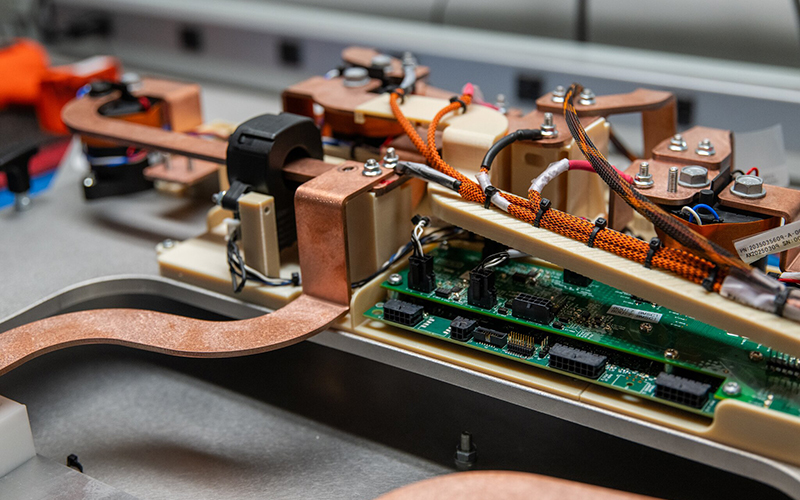

Re:Build DAPR applies its expertise to solving unique engineering challenges, particularly in extreme environments and highly specialized industrial applications. Our work spans industries where precision, durability, and innovation are critical to success. Whether it’s pushing the boundaries of temperature extremes, optimizing advanced energy storage, or designing custom reactor systems, Re:Build DAPR delivers solutions that go beyond conventional engineering.

Our high-performance systems are engineered to withstand extreme temperature conditions, from cryogenic environments (4K) to high-heat industrial processes (up to 2200°C).

We create precision-engineered cryogenic systems for fusion energy, deep geothermal, and directed energy technologies. Our expertise ensures efficient, stable operation in ultra-low-temperature environments where thermal management is critical.

Scalable and high-efficiency thermal energy storage solutions that enhance energy management and industrial process optimization. Our expertise enables the integration of renewable energy sources, improving grid reliability and reducing dependence on fossil fuels.

We engineer high-performance reactors for chemical processing, energy generation, and advanced material synthesis, ensuring efficiency, reliability, and safety. Our expertise in thermal management and system integration enables optimized scalability and industrial deployment.

Re:Build DAPR develops systems for extracting and utilizing geothermal energy from deep beneath the Earth’s surface. Our expertise includes millimeter-wave gyrotron drilling, exploring both cryogenic and alternative cooling methods to enhance system efficiency and feasibility.

Let’s talk about your unique challenges and how Re:Build DAPR can help you.