Re:Build DAPR Engineering is here to help turn your most complex technical challenges into high-performance, manufacturable solutions. Our team is made up of expert engineers, system designers, and program managers with backgrounds in a wide range of industries, bringing a multi-disciplinary approach to every project. We thrive on tackling physics-intensive problems, leveraging our deep expertise in precision engineering, automation, and industrial systems to bring your vision to life.

To date, Re:Build DAPR Engineering has helped companies design, build, and scale innovative technologies. From complex systems to precision manufacturing, our solutions have supported clients in turning ideas into real-world products while improving efficiency and reliability. Whether you’re developing a new system or optimizing an existing one, we’re here to help you navigate the journey from concept to production with confidence.

Whether you’re at the concept stage, refining a prototype, or scaling for full production, Re:Build DAPR’s structured Product & Manufacturing Readiness (PMR) Scale ensures that each step is executed with technical rigor and commercial viability in mind.

Customer Focus

Identifying market need, early research

Re:Build DAPR’s Role

Conducting feasibility studies, risk assessment

Customer Focus

Lab-scale testing, system concept validation

Re:Build DAPR’s Role

Conceptual design, early prototyping

Customer Focus

Developing and testing initial prototyping

Re:Build DAPR’s Role

Alpha prototype development, validation

Customer Focus

Subsystem integration, engineering modeling

Re:Build DAPR’s Role

System integration engineering analysis

Customer Focus

Refining prototypes, real-world testing

Re:Build DAPR’s Role

DFM assessments, process refinement

Customer Focus

Pilot system for deployment validation

Re:Build DAPR’s Role

Small-scale production support, testing

Customer Focus

Pre-production manufacturing preparation

Re:Build DAPR’s Role

Production transition, automation solutions

Customer Focus

Pre-production manufacturing preparation

Re:Build DAPR’s Role

Manufacturing validation, market scaling

Customer Focus

Full production, quality control systems

Re:Build DAPR’s Role

Post-launch support, efficiency improvements

Customer Focus

Full production, quality control systems

Re:Build DAPR’s Role

Long-term monitoring, product innovation

Systematic checkpoints reduce costly redesigns.

Moves products efficiently from prototype to production.

Aligns engineering with real-world production needs.

Provides a structured, proven path to commercialization.

Re:Build DAPR Engineering specializes in developing, integrating, and optimizing high-performance industrial solutions. Our expertise spans complex system design, automation, precision engineering, and advanced manufacturing, helping clients transform cutting-edge concepts into scalable, real-world applications.

We design and build industrial equipment, automation solutions, and custom machinery to help clients transition from research and prototyping to full-scale manufacturing.

Our team applies FEA, CFD, and techno-economic modeling to validate designs, optimize performance, and reduce risk.

We excel in automating previously manual processes, turning lab-scale operations into scalable, high-precision manufacturing workflows.

Re:Build DAPR engineers systems for challenging environments, including cryogenics, high-temperature processes, and energy storage.

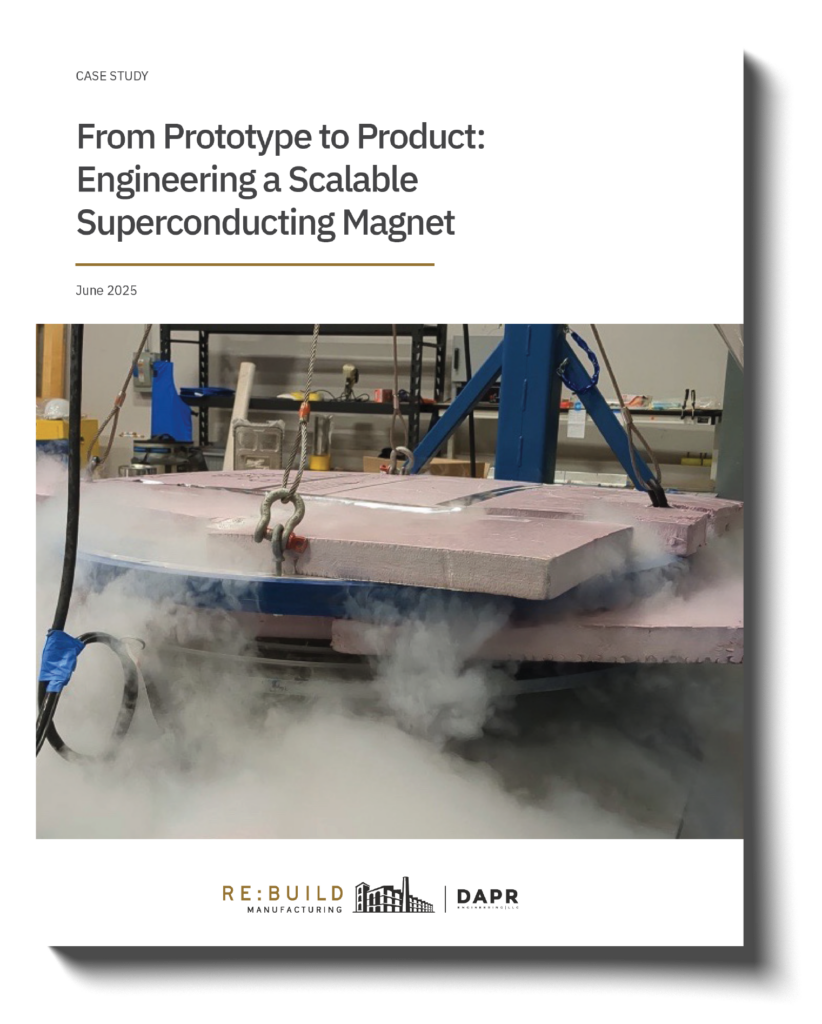

Scaling superconducting systems isn’t just difficult, it’s physics-intensive, integration-sensitive, and unforgiving under real-world conditions. This case study follows the journey of a first-of-a-kind magnet, engineered in partnership with a fast-moving energy startup, from concept through production-ready design.

Explore key lessons in cryogenic engineering, repeatable coil winding, thermal-mechanical integration, vibration-tolerant transport design, and agile program execution. Learn how Re:Build DAPR helped transform a complex prototype into a manufacturable product that performs reliably, every time, at scale.

At Re:Build DAPR Engineering, we help customers tackle their most complex engineering and manufacturing challenges. Our expertise in precision engineering, automation, and industrial system design enables us to deliver scalable, high-performance solutions across a range of industries. Explore our featured case studies to see how our innovative approach and technical excellence drive real-world success.

Re:Build DAPR Engineering combined sound engineering principles, innovative design approaches, solution-based processes, and effective project management as part of a collaborative team to deliver a high-throughput automated lab for the mass testing and processing of COVID–19 diagnostic testing.

Re:Build DAPR was able to utilize sound engineering principles combined with a collaborative and creative design approach to develop an Automated Punch Press machine that seamlessly integrated old, outdated technology with new. The machine was successful at isolating raw material, processing and neatly stacking each extrusion.

Re:Build DAPR Engineering combined sound engineering principles, innovative design approach, and solution-based processes to develop a first-generation metal 3D inkjet printing machine. The fast-track project met an accelerated schedule to deliver an alpha machine for introduction at a key industry tradeshow.

Across the United States, Re:Build Manufacturing is growing a family of engineering and manufacturing businesses whose combined experience creates an industrial powerhouse that is greater than the sum of its parts. Our expertise in operations management, product manufacturing, technical and engineering proficiency, and product lifecycle management is changing the way industrial America does business. Close collaboration yields more value for the good of all–our customers, our employees, and the community–for the very long term.

As one of Re:Build Manufacturing’s Member Companies, we remain the same DAPR as you know it, yet have added to our capabilities to generate even more value for our customers. We can now do more than ever across a wider variety of industries, all while serving customers from start-ups to large scale.

Looking to connect with an experienced team?

Look no further than Re:Build DAPR! We are excited to connect with you.