In the race to decarbonize industry, thermal energy storage is becoming a critical solution. It offers a way to bridge the gap between intermittent renewable generation, and the steady energy demands of industrial operations. However, designing a system that can safely and efficiently store energy as heat at temperatures above 1500°C is an extremely complex engineering challenge.

Re:Build DAPR worked alongside a clean energy innovator to design and deliver a high-temperature thermal battery. The system was built to absorb low-cost electricity, convert it into heat, and release that energy on demand to support continuous industrial use. Over the course of a multi-phase development effort, we helped advance the technology from early benchtop experiments to a modular prototype and ultimately a pilot-scale thermal storage unit.

This blog outlines the key design strategies, modeling techniques, and real-world engineering challenges we faced. These insights aim to help other teams pursuing scalable and cost-effective thermal energy storage solutions.

One of the first obstacles was the lack of reliable material data at the extreme temperatures we needed to reach. Many commercial data sheets stop at 1500°C, leaving a significant knowledge gap above that threshold. In our system, target temperatures approached 2000°C, where small material differences can have a major impact on performance and longevity.

To address this, we retrofitted a crystal-growth furnace into a thermal testing platform known as the Alpha system. This platform allowed us to run over 200 hours of continuous testing at high temperatures. We evaluated thermal block behavior, insulation effectiveness, and thermal interface performance in real thermal environments. We also tested how various gases interacted with materials to understand oxidation risks and insulation degradation.

A major takeaway from this phase was that real-world testing is essential. Material choices at these temperatures cannot rely solely on data sheets. Accurate thermal and chemical behavior must be validated through physical testing under operating conditions.

Instead of moving directly to a full-scale system, we designed a one-twelfth scale prototype called the Beta unit. This approach allowed us to reduce development risk and gain valuable insights before investing in large-scale production infrastructure.

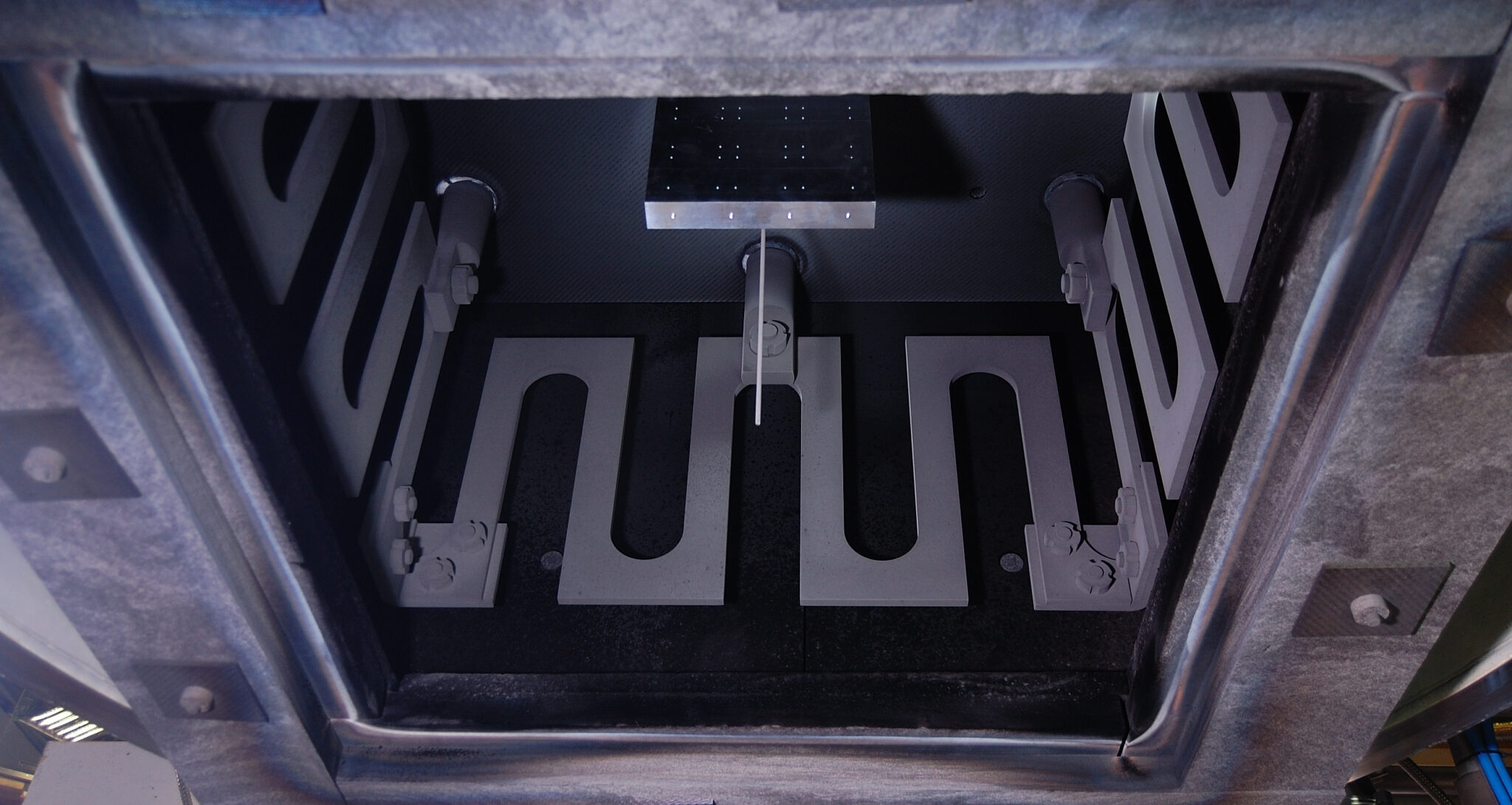

The Beta system featured a 6.5-metric-ton thermal block array, capable of storing megawatt-hours of thermal energy. It operated at internal temperatures of up to 2000°C and used high-current rod heaters delivering over 1000 amps. The insulation system combined rigid materials and soft felt to balance performance with cost.

Prototyping at this scale allowed us to validate everything from heating element geometry and insulation layout to gas flow. It also simplified transportation, installation, and commissioning activities, which made it easier to gather data in a production-like environment.

Thermal energy storage at these temperatures involves multiple overlapping systems. The electrical, thermal, structural, and fluid behaviors must be designed together, not in isolation. Early in the project, we developed a comprehensive modeling toolkit to guide decision-making and accelerate iteration.

Our modeling stack included:

One area of focus was surface-to-surface radiation modeling. We used view factor calculations in Matlab to determine the optimal positioning of discharge components relative to the hot zone. This enabled us to avoid physically moving discharge units during operation and simplified the overall system architecture.

One of the most practical lessons learned was the importance of planning for material availability. Some products such as rigid insulation panels had high demand or multi-week lead times, which could have delayed progress if not anticipated early.

We addressed this by placing long-lead orders in parallel with design activities. We also optimized the insulation stack using a hybrid approach, combining rigid and soft materials to achieve the required thermal performance without over-reliance on any one component.

For teams building similar systems, it is important to integrate sourcing considerations into the design phase. Thermal energy systems cannot succeed without the right materials in hand at the right time.

Thermal energy batteries are not just about storing heat. They must balance thermal retention, structural stability, electrical performance, gas control, and safe operation through all charge and discharge conditions. Viewing the system holistically was essential to solving the right problems at the right time. By validating key components early, building a modular prototype, and modeling interactions across physics domains, we delivered a pilot-scale system that can form the basis for commercial deployment.

High-temperature thermal energy storage has the potential to reshape how industrial heat is supplied in a low-carbon future. But unlocking that potential requires careful engineering, thorough modeling, and a willingness to solve problems across materials, physics, and manufacturing constraints.

Re:Build DAPR’s work on the Alpha and Beta systems provides a roadmap for other organizations seeking to design, scale, and deploy thermal energy storage solutions. We are proud to contribute to the future of clean energy with systems that store electricity as heat and release it exactly when and how it is needed.

If your team is working on thermal storage technologies, we are always open to sharing lessons learned and exploring how to bring your concepts to life.

Looking to connect with an experienced team?

Look no further than Re:Build Optimation! We are excited to connect with you.