Re:Build DAPR specializes in solving complex, physics-intensive engineering challenges, providing end-to-end solutions that bridge technology development and scalable manufacturing. Our expert team includes engineers in mechanical, electrical, controls, and industrial systems design. They bring deep expertise across a wide range of industries, including advanced energy systems, precision automation, high-speed industrial equipment, and manufacturing process optimization. We work with startups and industry leaders alike, helping transition groundbreaking innovations from concept to commercialization.

The Re:Build DAPR team is structured to tackle multidisciplinary, high-complexity engineering problems with a commitment to technical excellence, collaboration, and customer success.

Re:Build DAPR’s Project Lifecycle Process is more than a workflow, it is a proven methodology designed to de-risk innovation and accelerate commercialization. Unlike conventional engineering approaches, our structured stage-gated process ensures that every project moves forward with technical confidence, cost efficiency, and a clear path to scalable manufacturing.

We collaborate with clients to define project goals, technical requirements, and feasibility. This phase involves early-stage research, risk assessment, and concept exploration to ensure a solid foundation for development.

A clear project scope is critical to success. We develop detailed proposals, cost estimates, and project timelines, ensuring alignment between technical feasibility, business objectives, and manufacturability goals.

Our team refines early-stage designs, validates key concepts, and assesses manufacturability. Engineering simulations, feasibility studies, and system modeling help shape scalable, high-performance solutions.

We establish detailed system architecture, CAD models, and initial technical calculations to optimize performance, efficiency, and real-world application. Design iterations and validation occur in parallel to minimize risk.

Our team finalizes engineering drawings, electrical schematics, and subsystem integration plans, ensuring that designs are ready for manufacturing. This phase includes Design for Manufacturability (DFM) assessments to optimize cost and scalability.

We ensure the right components, materials, and suppliers are aligned for production. By integrating supply chain strategies with engineering decisions, we optimize cost, scalability, and lead times.

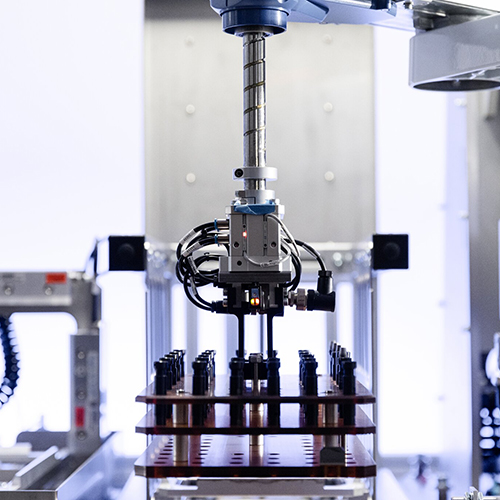

Our experts handle manufacturing, assembly, and system integration, followed by rigorous Factory Acceptance Testing (FAT). This ensures that products meet specifications before deployment.

We support on-site installation, Site Acceptance Testing (SAT), and real-world validation. This ensures smooth integration into customer operations, minimizing disruption and maximizing reliability.

Our partnership doesn’t end at deployment. We provide ongoing performance monitoring, troubleshooting, and iterative improvements, ensuring long-term system reliability and efficiency.

We work with clients to identify process optimizations, develop second-generation designs, and scale manufacturing capacity to support long-term growth and evolving industry needs.

Re:Build DAPR Engineering was founded in December 2014 with a mission to solve the most complex engineering challenges. Starting as a small team in a 1,600-square-foot office, the company quickly recognized the need to go beyond engineering services and provide full turnkey solutions to better support its customers. Over the years, DAPR has grown into a leader in industrial equipment design and custom automation, helping companies transition from research and prototyping to full-scale manufacturing.

2014

DAPR Engineering was founded by Steven Garrant and Keith Vaillancourt with a mission to solve complex, physics-driven engineering challenges.

2015

Welcomed the first employees and relocated to an 8,000-square-foot facility to accommodate a growing team and project demand.

2017

Strengthened expertise in custom automation and industrial equipment development, positioning DAPR as a go-to partner for turnkey solutions.

2019

Following continued success and expanding project scope, DAPR moved into a 20,000-square-foot facility, enabling greater capacity for larger, more complex programs.

2021

Joined Re:Build Manufacturing, gaining access to expanded manufacturing capabilities and cross-functional engineering resources.

2025

Transitioned into a brand-new, state-of-the-art, 60,000-square-foot facility to support ongoing growth and deliver even greater value to clients.

Founded in 2014 by Steven Garrant and Keith Vaillancourt, DAPR was built to solve physics-intensive engineering challenges. From humble beginnings in a 1,600-square-foot office, the company quickly grew into a leader in industrial equipment design and custom automation, bridging the gap between R&D and scalable manufacturing.

Re:Build DAPR helps both startups and industry leaders bring disruptive technologies to market. From thermal energy storage to reshoring U.S. battery manufacturing, we deliver automation, precision systems, and industrial process development. As part of Re:Build Manufacturing, we continue to scale innovations from prototype to production.

Since joining Re:Build Manufacturing in 2021, DAPR has nearly tripled in size. Now preparing to move into a 60,000-square-foot facility, we are expanding our capabilities to meet growing demand and deliver scalable, real-world solutions.

Sr. Mechanical Engineer

Knows: Thermal systems design, automated liquid handling equipment, custom lab device development, biotech instrumentation

Proud of: 7 years of industry experience across defense and biotech; contributed to Naval submarine systems at Electric Boat and helped advance DNA sequencing technology at a biotech startup

Passions: Mountain biking, hiking, camping, woodworking, traveling, home improvement

Principal Engineer

Knows: Control systems, SCADA platforms, field devices, industrial automation across multiple industries, modern automation solutions.

Degree(s): B.S. in Electrical Engineering, UMaine Orono (2013), with a focus in Industrial Automation.

Proud of: Solving difficult problems with modern automation solutions and thinking outside the box.

Passions: Tropical travel, sporting events, home improvement, hobby home automation, escape rooms, family time, and pets.

Mechanical Engineer

Knows: Mechanical design and engineering for rugged machinery, including experience with all-terrain tractors during a co-op with Doosan Bobcat.

Degree(s): B.S. and M.S. in Mechanical Engineering, University of Wisconsin–Madison, Class of 2023 and 2024.

Proud of: Contributing to real-world mechanical design projects while still in school, including hands-on experience with off-road equipment engineering.

Passions: Hiking, fishing, and rock climbing—always staying active and exploring the outdoors.

Mechanical Engineer

Knows: Wind engineering research and mechanical engineering fundamentals

Degree(s): B.S. in Mechanical Engineering from Rensselaer Polytechnic Institute (RPI)

Proud of: Contributing to research in wind engineering applications

Passions: Backpacking and graphic design

Principal Engineer

Knows: Packaging design for high-acceleration environments, GPS-aided inertial navigation, MEMS inertial instrumentation, precision machining, near-field photonics, thermophotovoltaics, and mechanical systems for extreme conditions.

Degree(s): B.S. and Ph.D. in Mechanical Engineering from MIT (1993, 2003); M.S. in Mechanical Engineering from the University of Michigan (1995).

Proud of: Contributing to classified defense projects, co-founding a thermophotovoltaics company, publishing 10 papers, and holding 7 patents across aerospace, sensing, and energy recovery technologies.

Passions: Tennis, bicycling, shooting pool, and attending live music events.

PM Supervisor

Knows: Mechanical design, electrical protection systems, electric vehicle components, project scheduling, engineering budgets, business case development, and client relationship management.

Degree(s): B.S. in Mechanical Engineering Technology from Wentworth Institute of Technology (2009); MBA with a concentration in Project Management and New Product Development from UMass Lowell.

Proud of: Leading design efforts in the electric vehicle industry and contributing to strategic planning and client success.

Passions: Boating, coaching recreational sports, watching the Patriots, spending time with his wife and two sons, and all things Disney.

Principal Engineer

Knows: SCADA systems, custom electrical and control system design, Siemens, Rockwell, and B&R platforms, and automation for the natural gas and machinery industries.

Degree(s): B.S. in Electrical Engineering from UMass Lowell, graduated Cum Laude.

Proud of: Transitioning into the controls and automation field through hands-on project work and designing systems from the ground up.

Passions: Photography, trail biking, and spending time with his daughter.

Principal Engineer

Knows: Automation equipment design and build, with experience in medical devices, consumer products, solar, lithium-ion batteries, and semiconductors.

Degree(s): B.S. in Mechanical Engineering from Worcester Polytechnic Institute (2004)

Proud of: Over 12 years of hands-on experience solving new challenges across a range of high-tech industries.

Passions: Spending time with his wife and two children, coaching soccer and basketball, visiting New Hampshire’s lakes and mountains, and home improvement projects.

Mechanical Engineer

Knows: Mechanical engineering in the energy sector, including natural gas transmission and distribution.

Degree(s): B.S. in Mechanical Engineering with a Minor in Business from Worcester Polytechnic Institute (2022).

Proud of: Competing as a Varsity Baseball Team member at WPI and gaining hands-on industry experience early in his career.

Passions: Fishing (saltwater and freshwater), golfing, skiing, and working on cars.

Mechanical Engineer

Knows: Mechanical engineering, project management, construction coordination, and internal operations at Re:Build DAPR through co-op experience.

Degree(s): B.S. in Mechanical Engineering from Wentworth Institute of Technology (2023).

Proud of: Building project management skills early in his career and returning to Re:Build DAPR as a full-time engineer after a successful co-op.

Passions: Hiking, camping, snowboarding, Brazilian Jiu-Jitsu, and working toward climbing all the high peaks of New England.

Mechanical Engineer

Knows: New product development in robotics and telecommunications industries.

Degree(s): B.S. and M.Eng. in Mechanical Engineering from Rochester Institute of Technology (2022).

Proud of: Contributing to innovation through early-career work in robotics and telecom product development.

Passions: Hiking, camping, and skiing.

Sr. Principal Designer

Knows: Mechanical design across automotive, semiconductor, and solar industries; capital equipment and custom design/build; internal networks and CAD systems support.

Proud of: Over 35 years of experience spanning multiple industries and roles, including technical support beyond design.

Passions: Woodworking, motorcycling, traveling, and SCUBA diving (PADI Open Water Instructor certified).

Sr. Engineering Supervisor

Knows: Manufacturing technologies, printing systems, jet engine development, mechanical systems design.

Degree(s): Bachelor of Science in Mechanical Engineering, Northeastern University, 1989.

Proud of: His extensive career across multiple industries, including key roles at Desktop Metal, DEKA, Beacon Power, Premium Power, and GE Aircraft Engines. His hands-on experience in designing rotating systems has made a significant impact in engineering.

Passions: Spending time with family, working on cars and projects with his boys, walking his dog, hosting pool parties, operating a Christmas tree farm with his wife.

Mechanical Engineer

Knows: Mechanical engineering with hands-on experience in laser energetics and industrial inspection technologies; design and fabrication using hand and machine tools.

Degree(s): B.S. and M.S. in Mechanical Engineering from Rochester Institute of Technology (2023).

Proud of: Contributing to cutting-edge research and technology during co-ops, and designing and building a custom electric bass.

Passions: Playing bass and guitar, rock climbing, reading, and creative design/fabrication projects.

Sr. Mechanical Designer

Knows: Mechanical design in defense and automated testing/tooling industries, 3D printing operations, and Six Sigma principles.

Degree(s): Associate’s in Mechanical Design Technologies from Nashua Community College; Six Sigma White Belt certified.

Proud of: Managing a 3D printing department and contributing to mechanical engineering projects across high-tech sectors.

Passions: Formula 1, tabletop and video games, skiing, and 3D printing.

General Manager

Knows: Engineering management, business development, new product development in industries such as consumer batteries, automotive batteries, life sciences, and crystal growth equipment

Degree(s): B.S. in Mechanical Engineering from Rensselaer Polytechnic Institute

Proud of: Leading engineering teams through new product development across diverse industries and taking on increasing responsibilities in management and business development

Passions: Golf, basketball, hiking, boating, snowmobiling, and making wood-fired pizza

Business Development & Sales Manager

Knows: Project management, estimation for mechanical contracting (commercial plumbing & HVAC), business development, and site leadership.

Degree(s): B.S. in Mechanical Engineering from the University of New Hampshire (2017).

Proud of: Successfully managing projects and leading business development efforts with a background in mechanical contracting.

Passions: CrossFit/weightlifting, boating, and photography.

Principal Engineer

Knows: Machine/automation design across medical device assembly, aerospace, automotive, packaging, and electronic assembly industries.

Degree(s): Attended Northeastern University.

Proud of: Over 24 years of experience in diverse industries, and a long career in soccer (retired after 31 years of play).

Passions: Cooking, traveling to warm places, and active involvement in The Sons of the American Legion.

Mechanical Engineer

Knows: Machine design, product development, metrology and optics, electric vehicle systems, ceramics, and glass industry applications.

Degree(s): B.S. in Mechanical Engineering from Worcester Polytechnic Institute (2021).

Proud of: Gaining hands-on experience across diverse industries through internships and co-ops.

Passions: Hiking, sailing, swimming, baking, cooking, and playing board games with friends and family.

Principal Engineer

Knows: Mechanical and manufacturing engineering, automation systems, tooling for medical and consumer products, and bolted joints/torque principles.

Degree(s): Dual degree in Mechanical and Manufacturing Engineering (2013).

Proud of: Gaining certifications in bolted joints and SolidWorks EPDM, and applying engineering skills to develop his own property into a camp.

Passions: Dirt biking, shooting, hiking, camping, and personal engineering projects.

Sr. Principal Engineer

Knows: Liquid chromatography equipment, optical detector systems, high-pressure pump design, 3D metal printing systems, mechanical design from concept to production.

Degree(s): B.S. and M.S. in Mechanical Engineering, Northeastern University.

Proud of: Leading the design of a production-scale 3D metal printer at Desktop Metal and over 16 years of innovative product development at Waters Corporation.

Passions: Spending time with family, working on cars and home projects, outdoor activities like fishing and hiking, playing sports, and candlepin bowling—where he’s been active in a league for 23 years.

Sr. Office Manager

Knows: Executive administration, HR coordination, financial operations, and organizational management across diverse industries (education, healthcare, real estate, and engineering).

Degree(s): B.S. in Early Childhood Education from Salem State University.

Proud of: Rejoining the DAPR team and excelling in organizing office operations, while fostering a productive and supportive work environment.

Passions: Cooking, reading, water aerobics, walking her Siberian Husky (Miika), and spending time with her five grandchildren.

Mechanical Supervisor

Knows: Product design in life sciences and defense industries, project leadership, and innovation in liquid handling technology (with several patents).

Degree(s): B.S. in Mechanical Engineering from the University of Massachusetts-Amherst (2003).

Proud of: Contributing to groundbreaking innovations in liquid handling and leading various projects to market in multiple industries.

Passions: Ice hockey (Level 4 USA Hockey Certified coach, head coach of youth hockey), supporting his children’s sports activities, traveling (especially to Hawaii), and riding his Harley in the White Mountains.

Sr. Engineering Advisor

Knows: Robotic systems, embedded controls, product development, machine design, suspension design, autonomous underwater vehicles.

Degree(s): B.S. and M.S. in Mechanical Engineering from MIT.

Proud of: Co-founding Active Shock LLC and developing semi-active dampers for military and construction equipment, and his extensive career designing race cars and autonomous vehicles.

Passions: Adrenaline sports (skiing, beach volleyball, dirt bikes, track days on his Ducati), working on vehicles, building dirt bike trails, house projects, and traveling (including backpacking and driving a Land Rover across Africa).

Sr. Technician

Knows: Building and testing industrial microwaves, engineering technician expertise.

Proud of: Over 20 years of experience at Microwave Techniques as an expert in industrial microwaves.

Passions: Motorcycle rides with his wife, hunting and fishing in the Northern woods of New Hampshire.

Controls Supervisor

Knows: Ocean floor mapping, autonomous underwater vehicles, cooling system design, high-speed assembly systems, inline vision inspection systems (3D line scan, 2D image).

Degree(s): B.S. in Mechanical Engineering from the University of New Hampshire, MBA focused on Project Management from SNHU.

Proud of: A diverse range of experiences in innovative engineering, from autonomous systems to high-speed assembly and vision inspection.

Passions: 3D printing, golfing, and paintball.

Sr. Buyer

Knows: Electrical systems, airframe and powerplant mechanics, aviation science, manufacturing engineering, sales, and leadership.

Degree(s): A.S. in Aviation Science, trained at East Coast Aero Technical School.

Proud of: A diverse 40-year career across roles such as assembler, technician, group leader, program leader, manufacturing engineer, and sales, with a background in restoring antique aircraft.

Passions: Golf, hiking, home improvement projects, gardening, and singing/playing guitar (often heard cheerfully singing around the office).

Mechanical Engineer

Knows: Automation, manufacturing systems, hybrid rocket design, engineering innovation.

Degree(s): B.S. in Mechanical Engineering from the University of New Hampshire, 2023.

Proud of: Creating a hybrid rocket system using candle wax as fuel for his senior project.

Passions: Fencing (coach at UNH), hiking the White Mountains, reading epic works like ‘Dune’.

Sr. Controls Engineer

Knows: Automation design and integration, GMP Biopharmaceutical Manufacturing, upstream and downstream processing, panel building, and troubleshooting across platforms including DeltaV, Rockwell, Siemens PCS7, TIA Portal, and Unicorn.

Degree(s): B.S. in Chemical Engineering with a minor in Biological Science, North Carolina State University, Class of 2016.

Proud of: 8 years of hands-on experience commissioning and validating biopharmaceutical manufacturing systems, and successfully transitioning to controls engineering with deep cross-platform automation expertise.

Passions: Hiking and trail biking with his wife, global travel (especially the Galapagos, Kauai, and India), home renovation, 3D printing, SCUBA diving, and skydiving—plus the unique experience of getting married in India.

Principal Engineer

Knows: Automation systems, PLC controls, custom machine building, life sciences industry, project management, and developing standards and software templates for efficiency.

Degree(s): B.S. in Mechanical Engineering, UMass Dartmouth, 2012

Art degree (previously pursued)

Proud of: Experience in both engineering and art, bringing a unique perspective to his work in automation and machine building. Developed efficient standards and software templates to improve customer support and project development.

Passions: Camping, riding his motorcycle, playing games with friends, and visiting breweries around New England.

Principal Project Manager

Knows: Project management, mechanical engineering in defense, custom machinery, and automation industries.

Degree(s): B.S. in Mechanical Engineering, University of Massachusetts Lowell.

Proud of: Over 7 years of project management experience built on a strong foundation in mechanical engineering across high-impact industries.

Passions: Spending time with his wife and two sons, and tackling home renovation projects.

Sr. Engineering Manager

Knows: Electrical engineering, medium and high voltage fuse design, hybrid protection devices, semiconductor fuses, test standards (IEEE), and engineering management.

Degree(s): B.S. in Electrical Engineering, Northeastern University.

Proud of: Being the primary inventor on a patent for a controllable fuse, contributing to IEEE standards, and leading design and management efforts across industrial and EV applications.

Passions: Running marathons, volunteering with the Winner’s Circle Running Club, and traveling with his wife for destination races.

Sr. Project Manager

Knows: Project management, mechanical construction, power electronics, semiconductors, automation, manufacturing.

Degree(s): B.S. in Mechanical Engineering and B.S. in Material Physics from the University of New Hampshire.

Proud of: 6+ years of project management experience across various industries including mechanical construction, power electronics, and automation.

Passions: Home improvement projects, vehicle restorations, sports, spending time with friends and family.

Sr. Mechanical Engineer

Knows: Automated machine design, assembly, CNC machining, and UR robots.

Degree(s): B.S. in Mechanical Engineering, University of New Hampshire.

Proud of: Experience in designing and automating machines, with a strong background in CNC machining and robotics.

Passions: Boating, dirt biking, snowmobiling, and working on cars.

Sr. Controls Engineer

Knows: Controls engineering, automation, temperature control systems, and designing accessible solutions, such as a bicycle for individuals with visual impairments.

Degree(s): B.S. in Electrical Engineering, University of New Hampshire, 2019.

Proud of: Creating a bicycle that allows visually impaired individuals to ride safely, combining engineering with a meaningful social impact.

Passions: Snowboarding, mountain biking, playing basketball, and unwinding with a good Netflix binge.

Principal Designer

Knows: Mechanical design, 3D modeling software, capital equipment, paper mill machinery, petro-chemical pumps, superconducting electric motors, wind turbines, cryogenic systems, automation, semiconductor systems, chemical filtration, vertical wafer cell packaging, test rigs, jigs, fixtures, tooling, weldments, castings, and sheet-metal.

Proud of: Bringing complex ideas to life and working across diverse industries to deliver manufacturable solutions.

Technician

Knows: Mechanical technician work, sports (football, basketball, volleyball, cornhole).

Degree(s): Lowell High School, 2009.

Proud of: Over 10 years of experience as a mechanical technician, contributing to engineering projects at Re:Build DAPR Engineering.

Passions: Playing sports and staying active through football, basketball, volleyball, and cornhole.

Principal Technician

Knows: Electro-mechanical technical maintenance, project management, group leadership, and technician roles across various industries.

Degree(s): Memorial High School, Manchester, NH.

Proud of: Over 20 years of experience in electro-mechanical maintenance and leadership roles, contributing to various industries.

Passions: Utilizing his broad range of technical and leadership experience to contribute to the Re:Build DAPR Engineering technician team.

Sr. Mechanical Engineer

Knows: Machine design, product development, silicon wafer, sensor, and toy manufacturing.

Degree(s): MEng in Mechanical Engineering, Dual B.S. in Mechanical Engineering and Design, Innovation, & Society, Rensselaer Polytechnic Institute.

Proud of: Experience in machine design and product development, with a focus on silicon wafer, sensor, and toy manufacturing. Playing and coaching on the Women’s Soccer team at RPI.

Passions: Staying active through sports, hiking, and snowboarding with friends.

Sr. Mechanical Engineer

Knows: Mechanical and biomedical engineering, high-precision design, cryogenic environments, laboratory automation, robotics, and composite materials.

Degree(s): Dual degree in Mechanical and Biomedical Engineering, Rensselaer Polytechnic Institute, 2019, Professional Engineering License, New Hampshire.

Proud of: Graduating summa cum laude and acquiring a diverse skill set in both mechanical and biomedical engineering, with expertise in high-precision systems and cryogenic environments.

Passions: Outdoor activities, including mountain and gravel biking, hiking, kayaking, sailing, and alpine/backcountry skiing.

Mechanical Engineer

Knows: Mechanical engineering, irrigation system design, water management, inclusive design, project management, and community engagement through music.

Degree(s): Mechanical Engineering, University of New Hampshire

Proud of: Work on the research and design of Modular Wheelchair Levers during college, and their ongoing commitment to inclusive design. Actively performing in the Barbershop quartet and chorus in Nashua, NH.

Passions: Sustainable gardening, creating pollinator habitats, rock climbing, dancing, crafting cosplay, playing the piano, engaging in lightsaber battles, and performing in the arts.

Sr. Mechanical Supervisor

Knows: Machine design, automation, pressure vessel design, vacuum design, ultra-high temperature design & materials (ceramics, graphites, refractory metals).

Degree(s): B.S. in Mechanical Engineering, University of New Hampshire.

Proud of: Solving challenging design problems and his ability to work across diverse engineering fields.

Passions: Traveling and adventuring with his wife and three kids, cooking, photography, and sports.

Sr. Director of Engineering

Knows: Industrial equipment design, process cooling, linear motion, vacuum technology, hot zone design, thermal engineering design, electronics packaging, cold plate design, CFD analysis, program management, field installations.

Degree(s): B.S. in Mechanical Engineering, University of New Hampshire, 2007

Proud of: His diverse career that spans engineering design, program management, and business development. Leading engineering efforts at Re:Build DAPR Engineering since 2019.

Passions: Spending time with his family, hiking, biking, skiing, golfing, working on home projects, and attending sporting events and concerts.

Sr. Mechanical Engineer

Knows: Bast fiber decortication, cryogenic and high-temperature mechanical design and analysis, precision automation, mechanical calculations, and data analysis.

Degree(s): B.S. and M.S. in Mechanical Engineering, Rensselaer Polytechnic Institute (RPI), 2021 & 2022.

Proud of: Gaining diverse engineering experience across advanced materials, automation, and extreme-environment design challenges, and contributing to innovative solutions through both research and applied projects.

Passions: Volleyball, racquetball, hiking, camping, and whitewater kayaking.

Sr. Technician

Controls Engineer

Knows: Robotics systems, automation solutions development, applied research in robotics.

Degree(s): M.S. in Robotics Engineering, Worcester Polytechnic Institute.

Proud of: Hands-on and automation development with real-world deployment experience across research and industry, spanning system integration and control.

Passions:

Bowling, pool, and hiking

Principal Controls Engineer

Knows: Industrial automation, controls systems, PLC, SCADA, MES development, and autonomous/remote vessel control systems.

Degree(s): B.S. in Electrical Engineering, Lehigh University, Class of 2009.

Proud of: Over 15 years of experience in automation, spanning critical industries like biotech and power generation, plus leading-edge work in autonomous marine systems.

Passions: Hiking and camping with his two dogs, dog training and boarding, and playing guitar and drums.

Sr. Mechanical Engineer

Knows: Mechanical design for high-rate production systems, composite structures, case-making automation, and Six Sigma methodologies.

Degree(s): B.S. in Mechanical Engineering from Rensselaer Polytechnic Institute. M.S. in Mechanical Engineering from Worcester Polytechnic Institute.

Proud of: Leading mechanical engineering for composite aperture production at BAE Systems and earning a Six Sigma Green Belt Certification.

Passions: Water skiing, hiking, and backpacking.

Sr. Technician

Knows: Electrical systems, manual machining, CNC lathes, and hands-on mechanical and electronic troubleshooting. OSHA 10 Certified.

Degree(s): N/A (Journeyman Electrician certification and machining experience)

Proud of: Bringing 18 years of combined electrical and machining expertise to a wide variety of projects—from tugboats to precision equipment—while raising two young boys.

Passions: Woodworking, electronics tinkering, multicopters, and playing guitar.

Operations Manager

Knows: Operations leadership, project and manufacturing management, business unit oversight, lean manufacturing, and Kaizen methodology including single-piece flow implementation.

Degree(s): B.A. in Business Management and Operations from Eastern Michigan University.

Proud of: Receiving Kaizen training in Japan from Chihiro Nakao and implementing single-piece flow lines in aerospace manufacturing.

Passions: Spending time with family, sports and sporting events, ocean boating and fishing, and tackling home projects.

Sr. Mechanical Engineer

Knows: Mechanical engineering, engineering management, laser service, maintenance, aircraft maintenance, and troubleshooting.

Degree(s): Bachelor of Science in Mechanical Engineering, University of Massachusetts, Lowell (May 2019). Master of Science in Engineering Management, University of Massachusetts, Lowell (May 2020). Professional Engineer Licensure, June 2024.

Proud of: My work across multiple fields, including laser services, aircraft maintenance, and being on the path to professional licensure.

Passions: Personal development, motorcycles, 4-wheeling, CrossFit, and hunting.

Mechanical Supervisor

Knows: Automated testing equipment, electronics manufacturing, nuclear industry operations.

Degree(s): B.S. in Mechanical Engineering, Clarkson University. MBA, Franklin Pierce University.

Proud of: Visiting most of the commercial nuclear reactors in the United States and one in Sweden during his time in the nuclear industry.

Passions: Home construction, spending time with his son.

Chief Engineer

Knows: Gearbox design, steel/copper mill drives, crystal growth furnaces, high-temperature materials, laser packaging and design (including DPSS and fiber lasers), vessel design per ASME section XIII Div. 1.

Degree(s): Master’s in Mechanical Engineering, University of Massachusetts Lowell

Proud of: His customer-focused problem-solving approach and the opportunity to support projects internationally, having traveled to Japan, China, South Korea, Finland, Czech Republic, Germany, and Austria.

Passions: Solving complex engineering problems and supporting global projects.

Sr. Technician

Knows: Aviation installation, electronic/mechanical systems, mobile technical training, basic MECP certification.

Degree(s): Mobile Technical Training, Basic MECP Certification.

Proud of: His previous roles as an aviation install tech at ProStar Aviation and E/M technician at Resonetics.

Passions: Mechanics, building and tinkering with cars and engines, fishing, cooking BBQ in his smoker, and semi-professional tennis.

Mechanical Engineer

Knows: Mechanical design, 3D printing, machining, amateur rocketry.

Degree(s): B.S. in Mechanical Engineering from Rochester Institute of Technology (RIT).

Proud of: Applying hands-on skills in design and prototyping to personal and professional projects.

Passions: Hiking, camping, traveling, amateur rocketry, and 3D printing/machining projects.

Mechanical Engineer

Knows: Test bench design, rapid prototyping, FMEA testing, mechanical testing and analysis, pump system performance evaluation, and interdisciplinary design integration.

Degree(s): B.S. in Mechanical Engineering with a Minor in Electrical Engineering and a focus in Bioengineering from Rochester Institute of Technology.

Proud of: Hands-on co-op experience contributing to medical device development at Abiomed and consumer product testing at Keurig Dr Pepper.

Passions: Tennis, kickboxing, hiking, painting, sculpting, sewing, and international travel (has visited 8 countries in Europe).

Controls Engineer

Knows:

Electrical systems design, control systems, and automation engineering.

Degree(s):

B.S. in Electrical Engineering from Rensselaer Polytechnic Institute (2025).

Proud of:

Applying a strong academic foundation in electrical engineering to real-world automation challenges.

Passions:

Sailing, restoration projects, and camping.

Sr. Project Manager.

Knows:

Process engineering, lean manufacturing, thermal spray coatings, CVD coatings, lithium-ion battery development, slot die coating, and equipment scale-up.

Degree(s):

B.S. in Chemical Engineering, Worcester Polytechnic Institute.

Proud of:

Gaining diverse industry experience as a Process Engineer at Coorstek (thermal spray coatings for semiconductors) and Coherent (CVD coatings for optical fibers), then helping scale up lithium-ion battery production at 24M Technologies, where he advanced from Process Engineer to Pilot Line Manager. Helped start up a factory in Thailand.

Passions:

Running, skiing, hiking, traveling, and spending time with his wife and dog.

Senior Controls Engineer

Knows:

Industrial automation, electric motors, powder bed fusion 3D printing, material science, and battery manufacturing, with 8 years of applied engineering experience.

Degree(s):

B.S. Mechanical Engineering, Rutgers University, 2017 (Summa Cum Laude)

Proud of:

Delivering software/hardware used in linear synchronous motors, powder bed 3D printers, and novel battery manufacturing.

Passions:

Training martial arts (Jiu Jitsu and Muay Thai), DIY projects, playing piano and guitar, watching old movies, and playing video games.

Mechanical Engineering Co-op

Knows:

CAD Design, rapid prototyping and 3D printing, mechanical engineering principles.

Degree(s):

Currently pursuing a B.S. in Mechanical Engineering, Wentworth Institute of Technology (expected 2027).

Proud of:

Inspiring future engineers by mentoring youth robotics teams.

Passions:

Spending time with friends, hiking and camping.

Let’s talk about your unique challenges and how Re:Build DAPR can help you.