How Manufacturers Are Automating Processes Once Thought Impossible

For decades, manufacturers have relied on manual assembly and production methods that seemed impossible to automate. These processes often depend on human touch, experience, and intuition. They are passed down through generations, perfected by craftsmen who can sense quality in ways that machines traditionally could not. But the manufacturing landscape has changed.

Expanding What’s Possible in Automation Through the Power of Re:Build Manufacturing

What truly sets us apart is the strength of the organization we are part of. As a member of Re:Build Manufacturing, we belong to a growing family of engineering and manufacturing companies united by a shared mission to revitalize American manufacturing and bring advanced production capabilities back home.

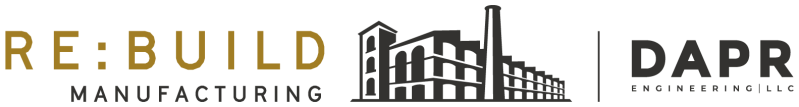

Engineering A Thermal Energy Battery

Re:Build DAPR worked alongside a clean energy innovator to design and deliver a high-temperature thermal battery. The system was built to absorb low-cost electricity, convert it into heat, and release that energy on demand to support continuous industrial use. Over the course of a multi-phase development effort, we helped advance the technology from early benchtop experiments to a modular prototype and ultimately a pilot-scale thermal storage unit.

Scaling Clean Energy: Engineering for High-Volume Anode Fabrication

In the transition to sustainable energy systems, innovation does not stop at new chemistries. It must extend into the manufacturing process itself. For one clean energy client, a novel iron anode held the promise of scalable, low-cost energy storage. But with a complex production method involving 900°C processing and a throughput of just one electrode per day, scale-up was a major bottleneck.

Engineering a Scalable Superconducting Magnet

Case study Turning a Breakthrough Prototype into a Scalable Superconducting Magnet Superconducting systems promise game-changing performance, but only if they can be scaled. This in-depth case study explores how Re:Build DAPR partnered with a leading energy startup to transform a delicate, cryogenic prototype into a repeatable, production-ready product. From coil winding and coldmass design to […]

Maintaining Bolt Preload with Belleville and Thermal Washers

In cryogenic systems, bolted joints are more than a mechanical convenience. They are a critical part of both structural integrity and thermal performance. However, what works at room temperature does not always hold up at 4 Kelvin. As components contract due to extreme cooling, bolts can lose preload, joints can loosen, and assemblies that were tightly clamped during fabrication may begin to shift or separate.

Getting Heat Out Fast: Thermal Contact Engineering for Cryogenic Systems

At cryogenic temperatures, even small thermal resistances can have a significant impact on system performance. When the goal is to cool a superconducting component to 4 Kelvin, every layer of material and every mechanical interface in the thermal path must be designed for maximum conductivity. That is why thermal contact engineering is one of the most critical elements of coldmass design.

In this post, we will explore how Re:Build DAPR analyzes thermal resistance across materials and joints, and how we optimize stack-ups, fasteners, and thermal interface materials to ensure rapid and reliable heat transfer at cryogenic temperatures.

What Is the Coldmass? Engineering for the Extreme at Cryogenic Temperatures

In the world of cryogenic engineering, where systems operate at temperatures as low as 4 Kelvin, there is one term that defines the core of performance, reliability, and complexity: the Coldmass. At Re:Build DAPR, the Coldmass represents the heart of our most advanced cryogenic systems, serving as the central structure where thermal, electrical, and mechanical systems converge under extreme conditions.

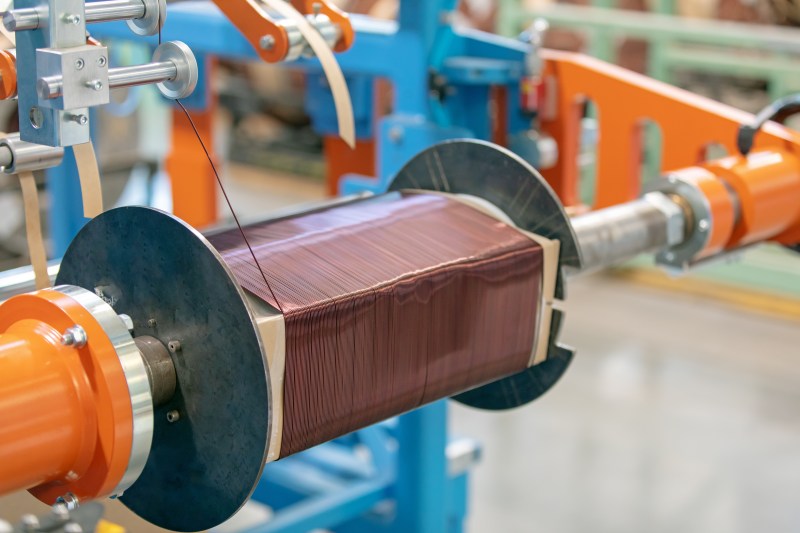

The Hidden Challenges of Coil Winding for Superconducting Systems

When building superconducting systems, coil winding is often treated as a technical afterthought, a simple fabrication step on the road to a functional magnet. But as we’ve seen at Re:Build DAPR, winding isn’t just about wrapping wire. It’s a delicate, high-stakes process that demands precision engineering, deep material understanding, and a proactive approach to process development.

Smarter Engineering Starts with the Right Process

When engineering projects fall short, it’s rarely because the idea was flawed. It’s because the execution lacked structure, alignment, and visibility. At Re:Build DAPR, we believe that delivering successful, complex systems requires more than technical skill, it demands a disciplined process that keeps customers informed, risks under control, and project goals on track from day one.